- FAA Order 8900.1, Volume 17, chapters 1-3; Documents associated with the rulemaking project that led to the publication of this rule are available at www.regulations.gov under Docket No. Contact Information. Wyrick Aviation Safety Flight Standards, Office of Safety Standards Assistant Manager, SMS Program Office, AFS-910.

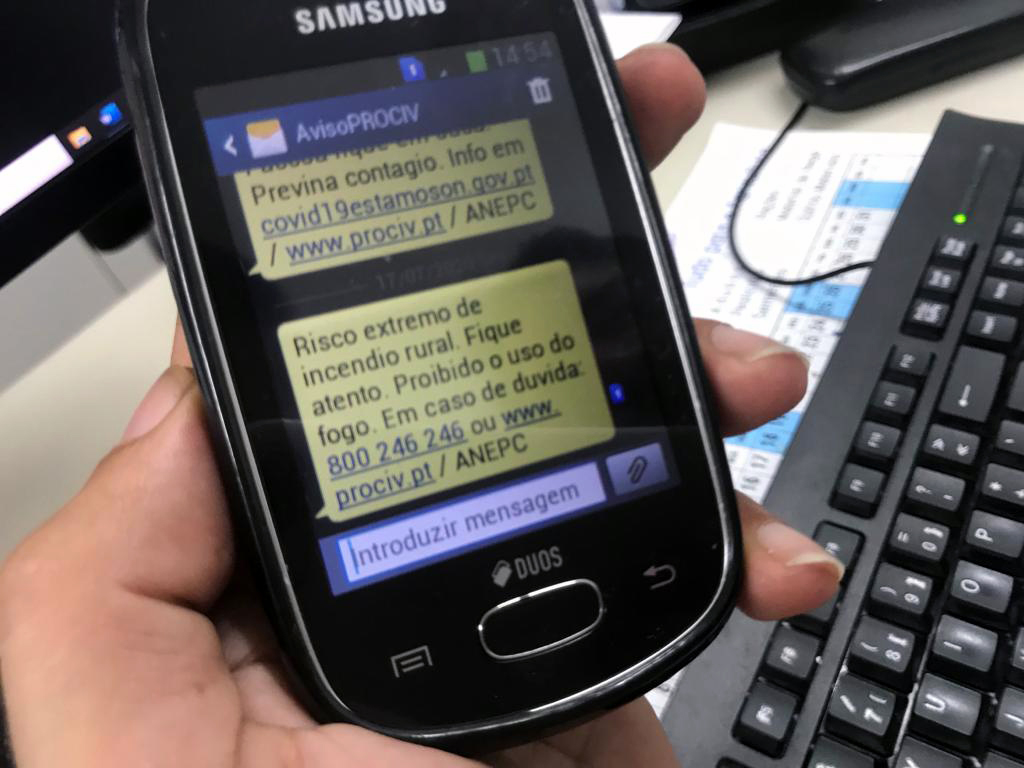

- SMS (short message service) is a text messaging service component of most telephone, Internet, and mobile device systems. It uses standardized communication protocols to enable mobile devices to exchange short text messages. An intermediary service can facilitate a text-to-voice conversion to be sent to landlines.

- SMS Current Release Software Title Build Date File Size.

Receive SMS online anonymously and fast, without a mobile phone. ReceiveSMS.cc is a free service to allow anyone to receive SMS messages online, the numbers are real SIM numbers and not virtual. How to use the site? Go to the requested country,then Click on the number you want to use, to view the messages, which arrive in 1-2 minutes. SMS(TAPPING) SCREW: An introduction: A 40 year evolution followed. It can be traced through four distinct phases of tapping screw design- thread forming, thread cutting, thread rolling and self-drilling.

* As newer versions of Adobe software are released, additional compatibility testing may be required. GMetrix will always work to support the latest software version of Adobe CC products whenever possible.

** Depending on your software version, Premiere Pro sample documents may require a short conversion process the first time a test is started. This will not impact your test timer.

1 Smoot

SMS(TAPPING) SCREW:

An introduction: A 40 year evolution followed. It can be traced through four distinct phases of tapping screw design- thread forming, thread cutting, thread rolling and self-drilling.

1 Samsung Galaxy S10 Plus

I. Thread forming screw are Types AB,.B, BP A, and C. Type C, with its machine threads and high-driving torques became obsolete with the introduction of thread rolling screws. It is no longer recommended for new designs. The only difference between Types AB, B and BP is their point design. AB is a threaded gimlet, Type B has a blunt point, and Type BP has an unthreaded gimlet. Call of duty zombies for ipad free download. Gimlet points center into preformed holes and facilitate thread start, but they are longer and need more blind side clearance. Also gimlet points tend to be a sharp and may damage other components in the assembly if they contact.

Ntpnp_pci0029. Thread Forming Tapping Screws - Type AB

Table 6 Dimensions of Threads and Points For Type AB Thread Forming Tapping Screws

| Nominal Size or Basic Screw Diameter | Threads Per Inch | D | d | L | ||||

| Major Diameter | Major Diameter | Minimum Practical Screw Lengths | ||||||

| Max | Min | Max | Min | 90° Heads | Csk Heads | |||

| 0 | 0.0600 | 48 | 0.060 | 0.054 | 0.036 | 0.033 | 1/8 | 5/32 |

| 1 | 0.0730 | 42 | 0.075 | 0.069 | 0.049 | 0.046 | 5/32 | 3/16 |

| 2 | 0.0860 | 32 | 0.088 | 0.082 | 0.064 | 0.060 | 3/16 | 7/32 |

| 3 | 0.0990 | 28 | 0.101 | 0.095 | 0.075 | 0.071 | 3/16 | 1/4 |

| 4 | 0.1120 | 24 | 0.114 | 0.108 | 0.086 | 0.082 | 7/32 | 9/32 |

| 5 | 0.1250 | 20 | 0.130 | 0.123 | 0.094 | 0.090 | 1/4 | 5/16 |

| 6 | 0.1380 | 20 | 0.139 | 0.132 | 0.104 | 0.099 | 9/32 | 11/32 |

| 7 | 0.1510 | 19 | 0.154 | 0.147 | 0.115 | 0.109 | 5/16 | 3/8 |

| 8 | 0.1640 | 18 | 0.166 | 0.159 | 0.122 | 0.116 | 5/16 | 3/8 |

| 10 | 0.1900 | 16 | 0.189 | 0.182 | 0.141 | 0.135 | 3/8 | 7/16 |

| 12 | 0.2160 | 14 | 0.215 | 0.208 | 0.164 | 0.157 | 7/16 | 17/32 |

| 1/4 | 0.2500 | 14 | 0.246 | 0.237 | 0.192 | 0.185 | 1/2 | 19/32 |

| 5/16 | 0.3125 | 12 | 0.315 | 0.306 | 0.244 | 0.236 | 5/8 | 3/4 |

| 3/8 | 0.3750 | 12 | 0.380 | 0.371 | 0.309 | 0.299 | 3/4 | 29/32 |

| 7/16 | 0.4375 | 10 | 0.440 | 0.429 | 0.359 | 0.349 | 7/8 | 1 1/32 |

| 1/2 | 0.5000 | 10 | 0.504 | 0.493 | 0.423 | 0.413 | 1 | 1 5/32 |

| See Notes | 3,4 |

Notes:

1 Sms How Many Character

- No extrusion of excess metal beyond apex of the point resuiting from thread rolling shall be permissible a slight rounding or truncation of the point is desirable.

- The width of flat at crest of thread shall not exceed 0.004 inch for sizes up to and including No.8, and 0.006 inch for larger sizes.

- Where specifying nominal size in decimals,zeros preceding decimal and in the fourth decimal place shall be omitted.

- Sizes shown in bold type are prefrred.

- For determining the effective grip of screws see Appdx. Vll, page H-58.

- For additional requirements , see introductiry Notes and General Data , page H-11.

Con Snt Sms 1

Thread Forming Tapping Screws - Types B And BP / Thread Cutting Tapping Screws- Types BF And BT

Table 7 Dimensions of Threads and Points for Types B and BP Thread Forming and Types BF and BT Thread Cutting Tapping Screws

| Nominal Size or Basic Screw Diameter | Threads Perinch | D | d | P | S | L | ||||||||

| Major Diameter | Major Diameter | Point Diameter | Point Taper Length | Minimum Practical Nominal Screw Lengths | ||||||||||

| Types B, BF, BT | Type BP | |||||||||||||

| Max | Min | Max | Min | Max | Min | Max | Min | 90° Head | Csk Heads | 90° Head | Csk Heads | |||

| 0 | 0.0600 | 48 | 0.060 | 0.054 | 0.036 | 0.033 | 0.031 | 0.027 | 0.042 | 0.031 | 1/8 | 1/8 | 5/32 | 3/16 |

| 1 | 0.0730 | 42 | 0.075 | 0.069 | 0.049 | 0.046 | 0.044 | 0.040 | 0.048 | 0.036 | 1/8 | 5/32 | 3/16 | 7/32 |

| 2 | 0.0860 | 32 | 0.088 | 0.082 | 0.064 | 0.060 | 0.058 | 0.054 | 0.062 | 0.047 | 5/32 | 3/16 | 1/4 | 9/32 |

| 3 | 0.0990 | 28 | 0.101 | 0.095 | 0.075 | 0.071 | 0.068 | 0.063 | 0.071 | 0.054 | 3/16 | 7/32 | 9/32 | 5/16 |

| 4 | 0.1120 | 24 | 0.114 | 0.108 | 0.086 | 0.082 | 0.079 | 0.074 | 0.083 | 0.063 | 3/16 | 1/4 | 5/16 | 11/32 |

| 5 | 0.1250 | 20 | 0.130 | 0.123 | 0.094 | 0.090 | 0.087 | 0.082 | 0.100 | 0.075 | 7/32 | 9/32 | 11/32 | 13/32 |

| 6 | 0.1380 | 20 | 0.139 | 0.132 | 0.104 | 0.099 | 0.095 | 0.089 | 0.100 | 0.075 | 1/4 | 9/32 | 3/8 | 7/16 |

| 7 | 0.1510 | 19 | 0.154 | 0.147 | 0.115 | 0.109 | 0.105 | 0.099 | 0.105 | 0.079 | 1/4 | 5/16 | 12/32 | 15/32 |

| 8 | 0.1640 | 18 | 0.166 | 0.159 | 0.122 | 0.116 | 0.112 | 0.106 | 0.111 | 0.083 | 9/32 | 11/32 | 7/16 | 1/2 |

| 10 | 0.1900 | 16 | 0.189 | 0.182 | 0.141 | 0.135 | 0.130 | 0.123 | 0.125 | 0.094 | 5/16 | 3/8 | 1/2 | 19/32 |

| 12 | 0.2160 | 14 | 0.215 | 0.208 | 0.164 | 0.157 | 0.152 | 0.145 | 0.143 | 0.107 | 11/32 | 7/16 | 9/16 | 21/32 |

| 1/4 | 0.2500 | 14 | 0.246 | 0.237 | 0.192 | 0.185 | 0.179 | 0.171 | 0.143 | 0.107 | 3/8 | 1/2 | 21/32 | 3/4 |

| 5/16 | 0.3125 | 12 | 0.315 | 0.306 | 0.244 | 0.236 | 0.230 | 0.222 | 0.167 | 0.125 | 15/32 | 19/32 | 27/32 | 31/32 |

| 3/8 | 0.3750 | 12 | 0.380 | 0.371 | 0.309 | 0.299 | 0.293 | 0.285 | 0.167 | 0.125 | 17/32 | 11/16 | 15/16 | 1 1/8 |

| 7/16 | 0.4375 | 10 | 0.440 | 0.429 | 0.359 | 0.349 | 0.343 | 0.335 | 0.200 | 0.150 | 5/8 | 25/32 | 11/8 | 1 1/4 |

| 1/2 | 0.5000 | 10 | 0.504 | 0.493 | 0.423 | 0.413 | 0.407 | 0.399 | 0.200 | 0.150 | 11/16 | 27/32 | 11/4 | 1 13/32 |

| See Note | 3 | 4 |

Notes:

1 Samsung Galaxy Note 8

- Points of screws shall be tapered and fluted or slotted as illustrated above for the respective types .The flute on Type BT screws shall have an included angle of 90 to 95 deg and the thread cutting edge located above the axis of screw. Tapered threads shall have unfinished crests within the point taper length. The flutes or slots shall extend through first full form thread beyond taper except for Type BF screws on which tapered threads may be complete at manufacturer's option and flutes may be one pitch short of first full form thread. Other details of taper and flute design shall be optional with manufacturer provided the screws meet the specified performance requirements.

- The width of flat at crest of thread shall not exceed 0.004 in. for sizes up to and including No. 8 and 0.006 in. for larger sizes.

- Where specifying nominal size in decimals zeros preceding decimal and in the fourth decimal place shall be omitted.

- Point diameters specified apply to screw blanks before roll threading.

- For determining the effective grip length of Type BP screws, see Appdx. V11, page H-58.

- For additional requirements refer to introductory Notes and General Data, page H-11.

Dimensions For Type C Tapping Screws

Table V1 Dimensions of Threads and Points for Types C Thread Forming Tapping Screws

| Nominal Size or Basic Screw Diameter | Threads per inch | D | P | S | L | ||||||||

| Major Dia | Point Dia | Point Taper Length | Determinant Lengths for Point Taper | Minimum Practical Nominal Screw Lengths | |||||||||

| For Short Screws | For Long Screws | ||||||||||||

| Max | Min | Ref | Max | Min | Max | Min | 90¢XHead | Csk Heads | 90¢XHead | Csk Heads | |||

| 2 | 0.0860 | 56 | 0.0860 | 0.0813 | 0.068 | 0.062 | 0.045 | 0.080 | 0.062 | 5/32 | 3/16 | 5/32 | 3/16 |

| 2 | 0.0860 | 64 | 0.0860 | 0.0816 | 0.070 | 0.055 | 0.039 | 0.070 | 0.055 | 1/8 | 3/16 | 1/8 | 5/32 |

| 3 | 0.0990 | 48 | 0.0990 | 0.0938 | 0.078 | 0.073 | 0.052 | 0.074 | 0.073 | 3/16 | 7/32 | 5/32 | 7/32 |

| 3 | 0.0990 | 56 | 0.0990 | 0.0942 | 0.081 | 0.062 | 0.045 | 0.080 | 0.062 | 5/32 | 3/16 | 5/32 | 3/16 |

| 4 | 0.1120 | 40 | 0.1120 | 0.1061 | 0.087 | 0.088 | 0.062 | 0.112 | 0.088 | 7/32 | 1/4 | 3/16 | 1/4 |

| 4 | 0.1120 | 43 | 0.1120 | 0.1068 | 0.091 | 0.073 | 0.052 | 0.094 | 0.073 | 3/16 | 7/32 | 5/32 | 7/32 |

| 5 | 0.1250 | 40 | 0.1250 | 0.1191 | 0.100 | 0.088 | 0.062 | 0.112 | 0.088 | 7/32 | 9/32 | 3/16 | 1/4 |

| 5 | 0.1250 | 44 | 0.1250 | 0.1195 | 0.102 | 0.080 | 0.057 | 0.102 | 0.080 | 3/16 | 1/4 | 3/16 | 1/4 |

| 6 | 0.1380 | 32 | 0.1380 | 0.1312 | 0.107 | 0.109 | 0.078 | 0.141 | 0.109 | 1/4 | 5/16 | 1/4 | 5/16 |

| 6 | 0.1380 | 40 | 0.1380 | 0.1321 | 0.113 | 0.088 | 0.062 | 0.112 | 0.088 | 7/32 | 9/32 | 3/16 | 1/4 |

| 8 | 0.1640 | 32 | 0.1640 | 0.1571 | 0.132 | 0.109 | 0.078 | 0.141 | 0.109 | 1/4 | 11/32 | 1/4 | 5/16 |

| 8 | 0.1640 | 36 | 0.1640 | 0.1577 | 0.136 | 0.097 | 0.069 | 0.125 | 0.097 | 7/32 | 5/16 | 7/32 | 9/32 |

| 10 | 0.1900 | 24 | 0.1900 | 0.1818 | 0.148 | 0.146 | 0.104 | 0.188 | 0.146 | 11/32 | 7/16 | 5/16 | 13/32 |

| 10 | 0.1900 | 32 | 0.1900 | 0.1831 | 0.158 | 0.109 | 0.078 | 0.141 | 0.109 | 1/4 | 11/32 | 1/4 | 5/16 |

| 12 | 0.2160 | 24 | 0.2160 | 0.2078 | 0.174 | 0.146 | 0.104 | 0.188 | 0.146 | 11/32 | 7/16 | 5/16 | 13/32 |

| 12 | 0.2160 | 28 | 0.2160 | 0.2085 | 0.180 | 0.125 | 0.089 | 0.161 | 0.125 | 5/16 | 13/32 | 9/32 | 3/8 |

| 1/4 | 0.2500 | 20 | 0.2500 | 0.2408 | 0.200 | 0.175 | 0.125 | 0.225 | 0.175 | 13/32 | 17/32 | 3/8 | 1/2 |

| 1/4 | 0.2500 | 28 | 0.2500 | 0.2425 | 0.214 | 0.125 | 0.089 | 0.161 | 0.125 | 5/16 | 13/32 | 9/32 | 3/8 |

| 5/16 | 0.3125 | 15 | 0.3125 | 0.3026 | 0.257 | 0.194 | 0.139 | 0.250 | 0.194 | 15/32 | 19/32 | 7/16 | 9/16 |

| 5/16 | 0.3125 | 24 | 0.3125 | 0.3042 | 0.271 | 0.146 | 0.104 | 0.188 | 0.146 | 11/32 | 15/32 | 5/16 | 15/32 |

| 3/8 | 0.3750 | 16 | 0.3750 | 0.3643 | 0.312 | 0.219 | 0.156 | 0.281 | 0.219 | 1/2 | 11/16 | 15/32 | 5/8 |

| 3/8 | 0.3750 | 24 | 0.3750 | 0.3667 | 0.333 | 0.146 | 0.104 | 0.188 | 0.146 | 11/32 | 1/2 | 5/16 | 1/2 |

| 7/16 | 0.4375 | 14 | 0.4375 | 0.4258 | 0.366 | 0.250 | 0.179 | 0.321 | 0.250 | 19/32 | 3/4 | 9/16 | 23/32 |

| 7/16 | 0.4375 | 20 | 0.4375 | 0.4281 | 0.387 | 0.175 | 0.125 | 0.225 | 0.175 | 13/32 | 9/16 | 3/8 | 17/32 |

| 1/2 | 0.5000 | 13 | 0.5000 | 0.4876 | 0.423 | 0.269 | 0.192 | 0.346 | 0.269 | 5/8 | 25/32 | 19/32 | 3/4 |

| 1/2 | 0.5000 | 20 | 0.5000 | 0.4906 | 0.450 | 0.175 | 0.125 | 0.225 | 0.175 | 13/32 | 9/16 | 3/8 | 17/32 |

| See Notes | 1 | 3 |

Note:

Sms1

- Where specifying ncminal size in decimals,zeros preceding decimal and in the fourth decimal place shall be omitted.

- Threads within point taper length shall have unfinished crests.

- Screws of these nominal lengths and shorter shall have point taper lengths specified for short screws. Longer lengths shall have point taper lengths specified for long screws.

- For additional requirements. Refer to Para. 2, page H-18.

* As newer versions of Adobe software are released, additional compatibility testing may be required. GMetrix will always work to support the latest software version of Adobe CC products whenever possible.

** Depending on your software version, Premiere Pro sample documents may require a short conversion process the first time a test is started. This will not impact your test timer.

1 Smoot

SMS(TAPPING) SCREW:

An introduction: A 40 year evolution followed. It can be traced through four distinct phases of tapping screw design- thread forming, thread cutting, thread rolling and self-drilling.

1 Samsung Galaxy S10 Plus

I. Thread forming screw are Types AB,.B, BP A, and C. Type C, with its machine threads and high-driving torques became obsolete with the introduction of thread rolling screws. It is no longer recommended for new designs. The only difference between Types AB, B and BP is their point design. AB is a threaded gimlet, Type B has a blunt point, and Type BP has an unthreaded gimlet. Call of duty zombies for ipad free download. Gimlet points center into preformed holes and facilitate thread start, but they are longer and need more blind side clearance. Also gimlet points tend to be a sharp and may damage other components in the assembly if they contact.

Ntpnp_pci0029. Thread Forming Tapping Screws - Type AB

Table 6 Dimensions of Threads and Points For Type AB Thread Forming Tapping Screws

| Nominal Size or Basic Screw Diameter | Threads Per Inch | D | d | L | ||||

| Major Diameter | Major Diameter | Minimum Practical Screw Lengths | ||||||

| Max | Min | Max | Min | 90° Heads | Csk Heads | |||

| 0 | 0.0600 | 48 | 0.060 | 0.054 | 0.036 | 0.033 | 1/8 | 5/32 |

| 1 | 0.0730 | 42 | 0.075 | 0.069 | 0.049 | 0.046 | 5/32 | 3/16 |

| 2 | 0.0860 | 32 | 0.088 | 0.082 | 0.064 | 0.060 | 3/16 | 7/32 |

| 3 | 0.0990 | 28 | 0.101 | 0.095 | 0.075 | 0.071 | 3/16 | 1/4 |

| 4 | 0.1120 | 24 | 0.114 | 0.108 | 0.086 | 0.082 | 7/32 | 9/32 |

| 5 | 0.1250 | 20 | 0.130 | 0.123 | 0.094 | 0.090 | 1/4 | 5/16 |

| 6 | 0.1380 | 20 | 0.139 | 0.132 | 0.104 | 0.099 | 9/32 | 11/32 |

| 7 | 0.1510 | 19 | 0.154 | 0.147 | 0.115 | 0.109 | 5/16 | 3/8 |

| 8 | 0.1640 | 18 | 0.166 | 0.159 | 0.122 | 0.116 | 5/16 | 3/8 |

| 10 | 0.1900 | 16 | 0.189 | 0.182 | 0.141 | 0.135 | 3/8 | 7/16 |

| 12 | 0.2160 | 14 | 0.215 | 0.208 | 0.164 | 0.157 | 7/16 | 17/32 |

| 1/4 | 0.2500 | 14 | 0.246 | 0.237 | 0.192 | 0.185 | 1/2 | 19/32 |

| 5/16 | 0.3125 | 12 | 0.315 | 0.306 | 0.244 | 0.236 | 5/8 | 3/4 |

| 3/8 | 0.3750 | 12 | 0.380 | 0.371 | 0.309 | 0.299 | 3/4 | 29/32 |

| 7/16 | 0.4375 | 10 | 0.440 | 0.429 | 0.359 | 0.349 | 7/8 | 1 1/32 |

| 1/2 | 0.5000 | 10 | 0.504 | 0.493 | 0.423 | 0.413 | 1 | 1 5/32 |

| See Notes | 3,4 |

Notes:

1 Sms How Many Character

- No extrusion of excess metal beyond apex of the point resuiting from thread rolling shall be permissible a slight rounding or truncation of the point is desirable.

- The width of flat at crest of thread shall not exceed 0.004 inch for sizes up to and including No.8, and 0.006 inch for larger sizes.

- Where specifying nominal size in decimals,zeros preceding decimal and in the fourth decimal place shall be omitted.

- Sizes shown in bold type are prefrred.

- For determining the effective grip of screws see Appdx. Vll, page H-58.

- For additional requirements , see introductiry Notes and General Data , page H-11.

Con Snt Sms 1

Thread Forming Tapping Screws - Types B And BP / Thread Cutting Tapping Screws- Types BF And BT

Table 7 Dimensions of Threads and Points for Types B and BP Thread Forming and Types BF and BT Thread Cutting Tapping Screws

| Nominal Size or Basic Screw Diameter | Threads Perinch | D | d | P | S | L | ||||||||

| Major Diameter | Major Diameter | Point Diameter | Point Taper Length | Minimum Practical Nominal Screw Lengths | ||||||||||

| Types B, BF, BT | Type BP | |||||||||||||

| Max | Min | Max | Min | Max | Min | Max | Min | 90° Head | Csk Heads | 90° Head | Csk Heads | |||

| 0 | 0.0600 | 48 | 0.060 | 0.054 | 0.036 | 0.033 | 0.031 | 0.027 | 0.042 | 0.031 | 1/8 | 1/8 | 5/32 | 3/16 |

| 1 | 0.0730 | 42 | 0.075 | 0.069 | 0.049 | 0.046 | 0.044 | 0.040 | 0.048 | 0.036 | 1/8 | 5/32 | 3/16 | 7/32 |

| 2 | 0.0860 | 32 | 0.088 | 0.082 | 0.064 | 0.060 | 0.058 | 0.054 | 0.062 | 0.047 | 5/32 | 3/16 | 1/4 | 9/32 |

| 3 | 0.0990 | 28 | 0.101 | 0.095 | 0.075 | 0.071 | 0.068 | 0.063 | 0.071 | 0.054 | 3/16 | 7/32 | 9/32 | 5/16 |

| 4 | 0.1120 | 24 | 0.114 | 0.108 | 0.086 | 0.082 | 0.079 | 0.074 | 0.083 | 0.063 | 3/16 | 1/4 | 5/16 | 11/32 |

| 5 | 0.1250 | 20 | 0.130 | 0.123 | 0.094 | 0.090 | 0.087 | 0.082 | 0.100 | 0.075 | 7/32 | 9/32 | 11/32 | 13/32 |

| 6 | 0.1380 | 20 | 0.139 | 0.132 | 0.104 | 0.099 | 0.095 | 0.089 | 0.100 | 0.075 | 1/4 | 9/32 | 3/8 | 7/16 |

| 7 | 0.1510 | 19 | 0.154 | 0.147 | 0.115 | 0.109 | 0.105 | 0.099 | 0.105 | 0.079 | 1/4 | 5/16 | 12/32 | 15/32 |

| 8 | 0.1640 | 18 | 0.166 | 0.159 | 0.122 | 0.116 | 0.112 | 0.106 | 0.111 | 0.083 | 9/32 | 11/32 | 7/16 | 1/2 |

| 10 | 0.1900 | 16 | 0.189 | 0.182 | 0.141 | 0.135 | 0.130 | 0.123 | 0.125 | 0.094 | 5/16 | 3/8 | 1/2 | 19/32 |

| 12 | 0.2160 | 14 | 0.215 | 0.208 | 0.164 | 0.157 | 0.152 | 0.145 | 0.143 | 0.107 | 11/32 | 7/16 | 9/16 | 21/32 |

| 1/4 | 0.2500 | 14 | 0.246 | 0.237 | 0.192 | 0.185 | 0.179 | 0.171 | 0.143 | 0.107 | 3/8 | 1/2 | 21/32 | 3/4 |

| 5/16 | 0.3125 | 12 | 0.315 | 0.306 | 0.244 | 0.236 | 0.230 | 0.222 | 0.167 | 0.125 | 15/32 | 19/32 | 27/32 | 31/32 |

| 3/8 | 0.3750 | 12 | 0.380 | 0.371 | 0.309 | 0.299 | 0.293 | 0.285 | 0.167 | 0.125 | 17/32 | 11/16 | 15/16 | 1 1/8 |

| 7/16 | 0.4375 | 10 | 0.440 | 0.429 | 0.359 | 0.349 | 0.343 | 0.335 | 0.200 | 0.150 | 5/8 | 25/32 | 11/8 | 1 1/4 |

| 1/2 | 0.5000 | 10 | 0.504 | 0.493 | 0.423 | 0.413 | 0.407 | 0.399 | 0.200 | 0.150 | 11/16 | 27/32 | 11/4 | 1 13/32 |

| See Note | 3 | 4 |

Notes:

1 Samsung Galaxy Note 8

- Points of screws shall be tapered and fluted or slotted as illustrated above for the respective types .The flute on Type BT screws shall have an included angle of 90 to 95 deg and the thread cutting edge located above the axis of screw. Tapered threads shall have unfinished crests within the point taper length. The flutes or slots shall extend through first full form thread beyond taper except for Type BF screws on which tapered threads may be complete at manufacturer's option and flutes may be one pitch short of first full form thread. Other details of taper and flute design shall be optional with manufacturer provided the screws meet the specified performance requirements.

- The width of flat at crest of thread shall not exceed 0.004 in. for sizes up to and including No. 8 and 0.006 in. for larger sizes.

- Where specifying nominal size in decimals zeros preceding decimal and in the fourth decimal place shall be omitted.

- Point diameters specified apply to screw blanks before roll threading.

- For determining the effective grip length of Type BP screws, see Appdx. V11, page H-58.

- For additional requirements refer to introductory Notes and General Data, page H-11.

Dimensions For Type C Tapping Screws

Table V1 Dimensions of Threads and Points for Types C Thread Forming Tapping Screws

| Nominal Size or Basic Screw Diameter | Threads per inch | D | P | S | L | ||||||||

| Major Dia | Point Dia | Point Taper Length | Determinant Lengths for Point Taper | Minimum Practical Nominal Screw Lengths | |||||||||

| For Short Screws | For Long Screws | ||||||||||||

| Max | Min | Ref | Max | Min | Max | Min | 90¢XHead | Csk Heads | 90¢XHead | Csk Heads | |||

| 2 | 0.0860 | 56 | 0.0860 | 0.0813 | 0.068 | 0.062 | 0.045 | 0.080 | 0.062 | 5/32 | 3/16 | 5/32 | 3/16 |

| 2 | 0.0860 | 64 | 0.0860 | 0.0816 | 0.070 | 0.055 | 0.039 | 0.070 | 0.055 | 1/8 | 3/16 | 1/8 | 5/32 |

| 3 | 0.0990 | 48 | 0.0990 | 0.0938 | 0.078 | 0.073 | 0.052 | 0.074 | 0.073 | 3/16 | 7/32 | 5/32 | 7/32 |

| 3 | 0.0990 | 56 | 0.0990 | 0.0942 | 0.081 | 0.062 | 0.045 | 0.080 | 0.062 | 5/32 | 3/16 | 5/32 | 3/16 |

| 4 | 0.1120 | 40 | 0.1120 | 0.1061 | 0.087 | 0.088 | 0.062 | 0.112 | 0.088 | 7/32 | 1/4 | 3/16 | 1/4 |

| 4 | 0.1120 | 43 | 0.1120 | 0.1068 | 0.091 | 0.073 | 0.052 | 0.094 | 0.073 | 3/16 | 7/32 | 5/32 | 7/32 |

| 5 | 0.1250 | 40 | 0.1250 | 0.1191 | 0.100 | 0.088 | 0.062 | 0.112 | 0.088 | 7/32 | 9/32 | 3/16 | 1/4 |

| 5 | 0.1250 | 44 | 0.1250 | 0.1195 | 0.102 | 0.080 | 0.057 | 0.102 | 0.080 | 3/16 | 1/4 | 3/16 | 1/4 |

| 6 | 0.1380 | 32 | 0.1380 | 0.1312 | 0.107 | 0.109 | 0.078 | 0.141 | 0.109 | 1/4 | 5/16 | 1/4 | 5/16 |

| 6 | 0.1380 | 40 | 0.1380 | 0.1321 | 0.113 | 0.088 | 0.062 | 0.112 | 0.088 | 7/32 | 9/32 | 3/16 | 1/4 |

| 8 | 0.1640 | 32 | 0.1640 | 0.1571 | 0.132 | 0.109 | 0.078 | 0.141 | 0.109 | 1/4 | 11/32 | 1/4 | 5/16 |

| 8 | 0.1640 | 36 | 0.1640 | 0.1577 | 0.136 | 0.097 | 0.069 | 0.125 | 0.097 | 7/32 | 5/16 | 7/32 | 9/32 |

| 10 | 0.1900 | 24 | 0.1900 | 0.1818 | 0.148 | 0.146 | 0.104 | 0.188 | 0.146 | 11/32 | 7/16 | 5/16 | 13/32 |

| 10 | 0.1900 | 32 | 0.1900 | 0.1831 | 0.158 | 0.109 | 0.078 | 0.141 | 0.109 | 1/4 | 11/32 | 1/4 | 5/16 |

| 12 | 0.2160 | 24 | 0.2160 | 0.2078 | 0.174 | 0.146 | 0.104 | 0.188 | 0.146 | 11/32 | 7/16 | 5/16 | 13/32 |

| 12 | 0.2160 | 28 | 0.2160 | 0.2085 | 0.180 | 0.125 | 0.089 | 0.161 | 0.125 | 5/16 | 13/32 | 9/32 | 3/8 |

| 1/4 | 0.2500 | 20 | 0.2500 | 0.2408 | 0.200 | 0.175 | 0.125 | 0.225 | 0.175 | 13/32 | 17/32 | 3/8 | 1/2 |

| 1/4 | 0.2500 | 28 | 0.2500 | 0.2425 | 0.214 | 0.125 | 0.089 | 0.161 | 0.125 | 5/16 | 13/32 | 9/32 | 3/8 |

| 5/16 | 0.3125 | 15 | 0.3125 | 0.3026 | 0.257 | 0.194 | 0.139 | 0.250 | 0.194 | 15/32 | 19/32 | 7/16 | 9/16 |

| 5/16 | 0.3125 | 24 | 0.3125 | 0.3042 | 0.271 | 0.146 | 0.104 | 0.188 | 0.146 | 11/32 | 15/32 | 5/16 | 15/32 |

| 3/8 | 0.3750 | 16 | 0.3750 | 0.3643 | 0.312 | 0.219 | 0.156 | 0.281 | 0.219 | 1/2 | 11/16 | 15/32 | 5/8 |

| 3/8 | 0.3750 | 24 | 0.3750 | 0.3667 | 0.333 | 0.146 | 0.104 | 0.188 | 0.146 | 11/32 | 1/2 | 5/16 | 1/2 |

| 7/16 | 0.4375 | 14 | 0.4375 | 0.4258 | 0.366 | 0.250 | 0.179 | 0.321 | 0.250 | 19/32 | 3/4 | 9/16 | 23/32 |

| 7/16 | 0.4375 | 20 | 0.4375 | 0.4281 | 0.387 | 0.175 | 0.125 | 0.225 | 0.175 | 13/32 | 9/16 | 3/8 | 17/32 |

| 1/2 | 0.5000 | 13 | 0.5000 | 0.4876 | 0.423 | 0.269 | 0.192 | 0.346 | 0.269 | 5/8 | 25/32 | 19/32 | 3/4 |

| 1/2 | 0.5000 | 20 | 0.5000 | 0.4906 | 0.450 | 0.175 | 0.125 | 0.225 | 0.175 | 13/32 | 9/16 | 3/8 | 17/32 |

| See Notes | 1 | 3 |

Note:

Sms1

- Where specifying ncminal size in decimals,zeros preceding decimal and in the fourth decimal place shall be omitted.

- Threads within point taper length shall have unfinished crests.

- Screws of these nominal lengths and shorter shall have point taper lengths specified for short screws. Longer lengths shall have point taper lengths specified for long screws.

- For additional requirements. Refer to Para. 2, page H-18.

Velodyne Sms 1 For Sale

II. Thread cutting screws are Types BF, BT, D, F, G, and T. types BF and BT have spaced threads, the other machine threads. Other differences related to the desgn of their cutting point. Before selecting a thread cutting screw, some thought should be given to the possible effect, if any, of the presence of small chips in the system.

Table 1 Type Designations for Tapping Screws and Metallic Drive Screws Bijoy 52 activation code 2014 free.